No stopping the beat

Sustainability – of our earth, our economy and the fast-paced beat we achieved during the World Cup – was a key theme at this year’s Sapics conference. FOCUS discovers what this means for transport companies.

Post Tournament Depression. It’s an actual syndrome, complete with acronym – PTD – and all. What it means, is that every country that has held the Soccer World Cup has gone through some kind of slump once it is all done. People miss the fun, the excitement, and feel that there is not much more to look forward to.

Of course in reality, this is not so. South Africa has plenty to be excited about. For starters we successfully held a world class event, one that is sure to bring tourists and investors alike into the country. South Africans need to continue with the energy and enthusiasm we exuded during the World Cup.

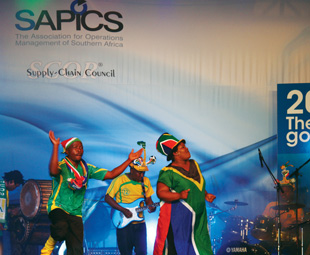

With the theme being “The Beat Goes On” this is what the 32nd Association for Operations’ Management of Southern Africa (Sapics) conference stressed in every way. The conference, held from 25 to 27 July, exceeded last year’s record of 930 delegates – this year over 1000 attended. Along with informative, largely interactive sessions from local and international experts, guests were treated to a very apt performance by DrumStruck at the conference’s opening – a South African show which gave most of us patriotic gooseflesh for the first time in a month.

A major theme throughout the conference was how companies can sustain the tempo we had going throughout the world cup. Douglas Kent, president of eKNOWtion and chairman of Supply Chain Council European Leadership Team, commented on how ‘South Africa’ and ‘World Class’ can be truly used synonymously for the first time ever, after the World Cup.

Prior to and during the tournament, hundreds of people were given training in many desperately important fields such as supply chain management. Our country has a huge pool of potential workers who lack the necessary training to be fully productive. Now that the event is finished, companies need to continue training and utilising our potential workforce, remembering that the eyes of the world are still on us, watching closely to see if we really can sustain the momentum gained during the running of the tournament.

Training was mentioned in every session at Sapics, and it needs to start from high school. Reuben Badana, president of Sapics, says “Sapics is very serious about education. As part of our battle against the lack of skills in the industry, we are launching new material that will soon be available to schools and training facilities.” Many speakers spoke about how perceptions of careers in industries such as supply chain and transport are often skewed. The right people are not attracted to the industries because they do not fully understand what they are about. It is therefore necessary to invest in educating the youth about the many exciting opportunities. Time and money also needs to be spent on training people once they have become interested. Supply chain and transport are suffering from a massive shortage of skilled workers, from drivers to mechanics and engineers, to managers and executives.

Training was mentioned in every session at Sapics, and it needs to start from high school. Reuben Badana, president of Sapics, says “Sapics is very serious about education. As part of our battle against the lack of skills in the industry, we are launching new material that will soon be available to schools and training facilities.” Many speakers spoke about how perceptions of careers in industries such as supply chain and transport are often skewed. The right people are not attracted to the industries because they do not fully understand what they are about. It is therefore necessary to invest in educating the youth about the many exciting opportunities. Time and money also needs to be spent on training people once they have become interested. Supply chain and transport are suffering from a massive shortage of skilled workers, from drivers to mechanics and engineers, to managers and executives.

Another aspect brought up by a multitude of speakers was that of “cooptition”. This is a combination of cooperation and competition, where competing companies work together in order to achieve maximum results. Karl Manrodt, associate professor, Department of Management, Marketing and Logistics, Georgia Southern University, talks of how companies need to work towards a “we win” rather than an “I win” situation in order to create long lasting relationships. Companies need to give their service providers motivation to want to continue the relationships – as long term relationships are ones where partners can learn about each other’s particular styles and needs, and become better at meeting these needs throughout the years.

Companies working with outsourced service providers also need to trust that the service providers are more qualified to do the particular job they have been hired to do than the company itself. “You wouldn’t go to a surgeon saying you needed heart surgery and then say, ‘This is how I want you to do it’,” Manrodt jokes. By this he means that businesses need to tell their service providers what their needs are, but not tell them how to tackle these. As an example, Manrodt speaks of how many companies outsource the management of their cafeterias. A well run company cafeteria will increase productivity of the company as it will keep employees healthy and on-site, thereby cutting down the amount of time they spend away from their workstations. This creates a “win” situation for the company. However, a well run cafeteria will also attract more people, thus increasing the profit margin for the outsourced service provider – a “win” situation for them. The company must allow for this increased profit margin, in this way nurturing the relationship. “Companies must allow each other to make money,” warns Manrodt.

“2010 is the year of sustainability,” claims Leisl de Wet, senior manager of sustainability at Barloworld Logistics Africa, South Africa. This must be considered by all companies wishing to attain any kind of international credibility. De Wet cautions that within this century, the global temperature has already risen 0.18oC, and is expected to rise another 1.1 to 1.6oC. She explains that the temperature cannot rise 2oC without drastically changing the earth’s ecosystems. De Wet elaborates that sustainability comprises three factors: environmental, economic and social. “One factor cannot be bigger or more important than the others; there needs to be a balance.”

“2010 is the year of sustainability,” claims Leisl de Wet, senior manager of sustainability at Barloworld Logistics Africa, South Africa. This must be considered by all companies wishing to attain any kind of international credibility. De Wet cautions that within this century, the global temperature has already risen 0.18oC, and is expected to rise another 1.1 to 1.6oC. She explains that the temperature cannot rise 2oC without drastically changing the earth’s ecosystems. De Wet elaborates that sustainability comprises three factors: environmental, economic and social. “One factor cannot be bigger or more important than the others; there needs to be a balance.”

De Wet says that keeping a company green also means keeping it lean. “Using water and electricity are non-value added activities. Eliminating wastage of these resources as much as possible will not only help the environment, but help your company too,” says De Wet. “We must learn to recognise hidden environmental waste.”

Adrian von Tonder, Barloworld Logistics Africa’s technical general manager, goes on to elaborate how necessary it is for the transport industry to acknowledge the importance of sustainability. “Sustainable transport means best practice,” says Von Tonder. “This is a matter of constantly doing the basics correctly.” He explains that in order to do this transport companies need to adhere to the National Road Traffic Act. “This means having roadworthy vehicles and trailing equipment, adhering to axle mass limits and operating within legal speed limits, as well as selecting the correct vehicle configuration,” he elaborates. Another aspect that cannot be ignored is driver wellness. This involves driver training, being mindful of driving hours in order to avoid fatigue, consistent driver evaluations, driver briefing and debriefing, and encouraging communication between operators and their drivers. “These are tough times,” admits Von Tonder, “but we cannot undercut rates. So often best practice basics are the first to suffer, but it is these we need to focus on.” Barloworld Logistics is following these basics with their “Green Trailer” – see pages 39-41 of this issue of FOCUS.

Abrie de Swardt, marketing director, Imperial Logistics South Africa, strongly agrees with De Wet and Von Tonder. “Sustainability is the new BEE. Greener standards will not be optional for companies to be viable, so it is best to get in line with these standards before they are forced upon us,” he cautions.

On the whole, Sapics 2010 reminded delegates how sticking to the basics, not cutting corners and making wise investments in aspects such as training and sustainability can in fact save companies’ money in the long run, as well as make them run more efficiently and productively.

Published by

Focus on Transport

focusmagsa