On track with ZF

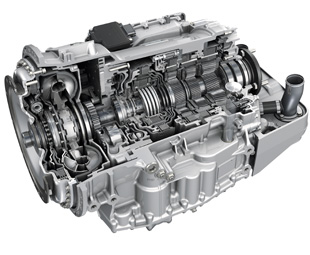

The new ZF EcoLife gearbox is a sterling example of modern electronic technology and mechanical engineering brought together for improved performance – both on the road and at the pumps, discovers GAVIN MYERS

Excitement was the name of the game when ZF Services South Africa (ZF SSA) recently hosted its most-valued clients and the media to a track-experience customer day at Pretoria’s Zwartkops Raceway. With the aim of showing off its latest EcoLife gearbox, the company had an action-packed day in store – including skidpan gymkhana competitions and race-track laps in German sedans.

Of course, EcoLife was the star of the show and presenters Thierry Dupin and Richard Bleunven, from ZF head-quarters, were keen to point out the advanced features of this new-generation transmission. The guests were piled into a bus and witnessed the EcoLife transmission’s capabilities on the actual circuit.

EcoLife is the successor to ZF’s Ecomat transmission – originally launched to the market way back in the 1970s. This new six-speed fully automatic transmission features a host of innovations to promote economy and ecology, especially in partnership with new engines and modern emission regulations.

Notable among these are extended oil change intervals of up to 180 000 km (this can vary from 120 000 km right up to 240 000 km, depending on the vehicle application) and a longer service life – in large part due to the new dual transmission oil cooling system, which can withstand operating temperatures of up to 120ºC. To aid this longevity, ZF developed a unique transmission fluid for the EcoLife gearbox called EcoFluid Life.

Compared to other modern powershift transmissions, EcoLife transfers up to 25 percent more torque to the drive wheels. The transmission can also handle over 2 000 Nm input torque, and features an integrated primary retarder that itself – depending on the vehicle’s configuration of components such as the cooling system and software – provides a maximum braking power of 2 000 Nm.

Compared to other modern powershift transmissions, EcoLife transfers up to 25 percent more torque to the drive wheels. The transmission can also handle over 2 000 Nm input torque, and features an integrated primary retarder that itself – depending on the vehicle’s configuration of components such as the cooling system and software – provides a maximum braking power of 2 000 Nm.

This was something ZF was keen to demonstrate to us, with the demo bus performing emergency braking with, and without, passengers on board … The company even went so far as to put the bus up against a Mercedes-Benz C-class in a tyre-screeching braking contest. The far smaller and lighter sedan only managed to stop from 60 km/h just a few metres before the bus. It really was impressive to witness the sheer emergency stopping power of the bus.

“A city bus is stopped 30 to 50 percent of the time,” notes Bleunven. “That’s why we have the Automatic Idle Shift (AIS) feature that is activated when the vehicle is about to be stopped. The software disconnects the driveline from the engine, reducing drag which, in turn, reduces fuel consumption.” At low speeds, the system aims to keep the bus in the correct gear so as to allow smooth and steady acceleration, while using less fuel.

Moving back from the brake pedal to the accelerator, the EcoLife gearbox features a hydraulic torque converter to give “traction power” to the bus as well as a lock-up clutch. “The main purpose of this is to allow the driver to easily start moving a very heavy bus – the torque converter allows us to convert the 2,5 to three times the engine power to move it off,” says Bleunven. “As soon as the bus is moving at, between five and 10 kilometres an hour, the torque converter is closed and the lock-up clutch is engaged for a straight mechanical connection,” he continues.

The folk from ZF were also keen to demonstrate the “brains” behind EcoLife; the ZF TopoDyn software. This impressive feature is a dynamic drive program that selects the correct gear and gear shift points, depending on topography and driving resistance (i.e. how much weight the vehicle is carrying). The software calculates the optimum shift points and strategies (“Normal”, “Eco” and “Power”) in a continuous and variable way, with no decision required on the part of the driver.

The folk from ZF were also keen to demonstrate the “brains” behind EcoLife; the ZF TopoDyn software. This impressive feature is a dynamic drive program that selects the correct gear and gear shift points, depending on topography and driving resistance (i.e. how much weight the vehicle is carrying). The software calculates the optimum shift points and strategies (“Normal”, “Eco” and “Power”) in a continuous and variable way, with no decision required on the part of the driver.

As Bleunven explains, should the bus begin to climb uphill, the system will automatically change from the Normal or Eco modes to the Power mode, in order to avoid the driver having to apply too much more throttle.

ZF is keen to point out that TopoDyn is not a GPS-based or sensor-assisted system, and so its major advantage is that it does not need to “learn” the topography and provides a flexible balance between performance and economy at all times. This balance, on its own, leads to fuel savings from five to eight percent.

Finally, a new torsional vibration damper allows for very smooth gear changes and, in conjunction with all the high-tech electronic and mechanical features built into the gearbox, any transmission jerk or driveline shunt is absent.

Exciting stuff indeed!

Published by

Focus on Transport

focusmagsa