Original aftermarket

We explore some initiatives by vehicle original equipment manufacturers (OEMs) to serve the aftermarket needs of their customers

The old adage of the salesmen selling the first truck, but the aftersales team selling every truck thereafter, remains true today – aftersales backup is a non-negotiable for the professional transport operator.

If there was ever any doubt as to the importance of running a comprehensive OEM aftersales programme, one needs look no further than the doorstep of Hino South Africa.

The brand has recently notched up its tenth successive quarter at the top of the Scott Byers Comparative Customer Satisfaction Monitor; both in the combined score and in the Service and Parts categories. (It ranked second in the Sales category following the latest survey in the second quarter of 2017.)

Hino performed particularly strongly in the Parts category, gaining top scores in all eight comparative aspects of parts supply surveyed.

“We realise that customer satisfaction is a moving target, and generally in South Africa the movement is upward in terms of the Scott Byers scores. This means that we must continue to try even harder to satisfy the needs of our customers to retain our leading position,” says Ernie Trautmann, vice president of Hino SA.

According to Trautmann, maintaining such aftersales excellence involves building and maintaining strong relationships between Hino Japan, Hino South Africa, its suppliers and the Hino dealer network.

Innovation is also required in the fast-paced world of OEM aftermarket service, as borne out by MAN Automotive, which has recently launched numerous aftersales initiatives such as the innovative MAN ecotrade concept.

MAN ecotrade is the latest addition to the MAN Genuine Parts programme and allows for savings of up to 25 percent on selected new MAN genuine parts – in return for used MAN genuine parts.

The customer also benefits from long-term commitment to price advantages throughout the year, as well as extended life of vehicles out of warranty, as replacement parts are genuine (albeit discounted).

The feel-good spin-off is that this aftermarket trade-in initiative ensures that old parts are recycled in an environmentally friendly manner. Recycling of old parts allows for a reduction in the energy-intensive production of new parts (and the environmental emissions that this unfortunately creates).

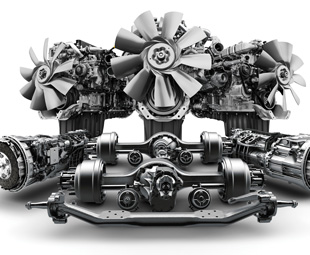

Naturally, each OEM offers its own aftermarket solutions to customers. Refurbished or remanufactured parts, branded oils and lubes, and specialised replacement parts (such as batteries) are but a few.

Those that go the extra mile place special emphasis on the behind-the-scenes logistics related to aftermarket replacement parts.

Iveco, for example, uses a radio-frequency identification device (RFID) to identify and track individual replacement parts, from arrival in the warehouse to delivery to the workshop. This, the company says, protects the customer and their vehicle from the risks posed by counterfeit goods.

It’s initiatives such as these that sell the next truck…

Published by

Focus on Transport

focusmagsa