More to these little bits of support

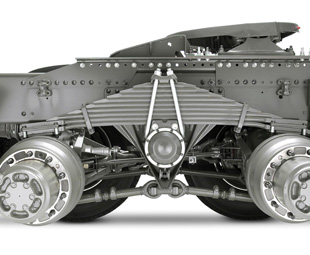

While a vehicle’s suspension bushes cannot be seen, they are important to its stability, comfort and safety. WILLIAM GEORGE explores the latest developments behind these little components that help support a vehicle

Bushes are a form of mounting used in all vehicles. They provide an interface between two parts and serve to dampen energy, which is then transmitted through the bushes. The use of bushes helps to control movement in suspension systems and other parts such as engine and transmission mounts.

Bushes also cushion the system, minimising wear, noise and vibration, and aid the comfort and handling of the vehicle. They can be made from materials such as rubber, copper, polyurethane and nylon, and vary in shape and size depending on the components for which they are designed.

There are different types of bushes available which offer distinctive benefits – some of the rubber-based ones deteriorate more quickly than those made from polyurethane, which, however, tend to squeak with time. Polyurethane has some unique properties that make it ideal for use in bushes, such as flexibility and resistance to grease, cuts and abrasions.

Polyurethane and rubber materials are both measured in durometer, which indicates the hardness of the material. A rubber tyre, for example, has a durometer of Shore 60A, while polyurethane durometer ranges from 80A to 95A. As a result, bushes made from polyurethane are likely to outperform those made from rubber. On the other hand, rubber bushes do not need lubrication and do not squeak.

Some advances have been made in the manufacture of suspension bushes. Vesconite Bearings provides some of the latest innovations and offers self-lubricating bushes, which assist in cutting costs of maintenance and downtime.

Eddie Swanepoel, technical representative at Vesconite Bearings, says that some conventional bushes, for example those made from nylon, swell when exposed to water, which results in radial expansion and seizure onto the shaft. As nylon absorbs moisture it also tends to creep.

“Vesconite and Vesconite Hilube bushes do not require lubrication, which makes these two products ideal maintenance-free alternatives to those made from nylon,” says Swanepoel.

Vesconite Bearings partnered with global experts in truck and trailer technology to come up with advanced solutions in suspensions.

“We did in-field tests, where we fitted Vesconite and conventional bushes on trailers, which travelled the same routes every day. The Vesconite bushes lasted almost four-times longer than the conventional ones,” says Nellis Nel, mechanical engineer at Fruehauf Components.

Maintenance of conventional bushes may be costly and increase downtime. It is advisable for vehicle owners to consult the original equipment manufacturer, or experts, before upgrading to new bushes.

When considering buying bushes, vehicle owners should consider the vehicle model and its maintenance costs, and source bushes that will suit their specific needs for increased productivity and efficiency.

Published by

Focus on Transport

focusmagsa