Six or seven axles?

The recent FOCUS Truck Test (see FOCUS May) raised the old debate of whether a 6×4 truck tractor is more economical to run coupled to a set of interlink trailers (seven-axle rig) or to a three-axle trailer (six-axle rig)

Too often, heavy commercial vehicles are purchased and selected for an application without considering the overall productivity of the unit. Obviously, the purchase price for a six-axle rig is cheaper than a seven-axle rig, but the initial purchase price should not be the main deciding factor when buying a new vehicle – vehicle productivity has also to be taken into account.

To measure vehicle productivity, three factors should be considered: legal payload, average trip speed and fuel consumption.

The higher the productivity figure, the more efficient the truck or vehicle combination will be. The productivity is calculated by multiplying the payload (tonnes) by the average trip speed and then dividing the answer by the average fuel consumption (l/100 km).

Floor deck space has to be taken into consideration when running a six-axle rig as, according to Road Traffic Act regulations, a truck tractor coupled to a single semi-trailer cannot exceed 18,5 m in overall vehicle length. This restricts the loading deck space on the trailer to an approximate length of 14,5 m.

On the other hand, truck tractors coupled to a set of interlink trailers offer a loading deck space of approximately 18 m, making this the unit ideal for operators who transport ISO containers.

To compare the total vehicle operating costs between the six- and seven-axle rigs, I asked Hellberg Transport Management (HTM) to provide the relevant information. This well-known and respected company specialises in producing accurate computer-simulated, estimated heavy-vehicle operating costs, as well as a host of other simulations for the trucking industry.

HTM’s TransSolve selected the Johannesburg/Durban route and ran the simulation over a period of 60 months, covering a total annual distance of 144 000 km.

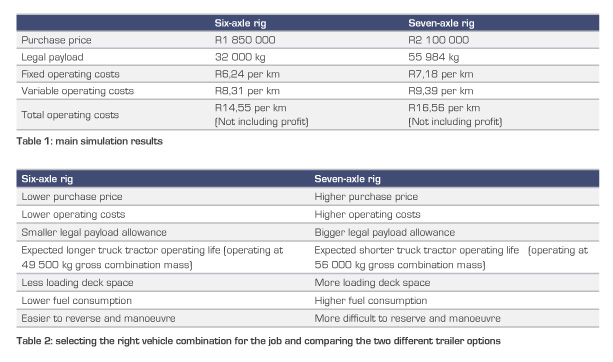

See table 1 for the main results.

Selecting the right vehicle and trailer combination for the operation is a critical decision in most operations, as this will have a direct result on profitability.

When selecting the vehicle combination and comparing the two different trailer options, the main facts should be examined (see table 2).

My advice, therefore, is to examine your operation in detail and establish all the factors that need to be considered, then, together with your vehicle supplier, endeavour to select the right truck tractor and trailer combination.

The modern computer technology that is available at truck dealers today can assist in the selection of the most appropriate vehicle, and makes the process much easier than in the past.

Ask your truck supplier to run a TransSolve simulation demonstration and include lots of variables … what if we use a less-powerful truck tractor; what if we couple a tridem-axle trailer instead of an interlink set of trailers; what if we reduce the speed?

The answers to these questions will assist you to make the right choice. Remember, the secret is to have the right truck tractor and trailer combination for the job and one that suits your particular operation.

One of this country’s most respected commercial vehicle industry authorities, VIC OLIVER has been in this industry for over 50 years. Before joining the FOCUS team, he spent 15 years with Nissan Diesel (now UD Trucks), 11 years with Busaf and seven years with International.

Published by

Focus on Transport

focusmagsa

!

From 1 Apri

!

From 1 Apri

Big news from FOCUS on Transport + Logist

Big news from FOCUS on Transport + Logist

FUSO: Driving the Future of Mobile Healthc

FUSO: Driving the Future of Mobile Healthc

A brand

A brand

Wondering about the maximum legal load for a

Wondering about the maximum legal load for a

The MAN hTGX powered by a hydrogen combus

The MAN hTGX powered by a hydrogen combus

Exciting News for South African Operators

Exciting News for South African Operators