Part and parcel of the future

The IAA is undoubtedly the biggest bi-annual event on the transport industry’s calendar, showcasing the latest and greatest the trade has to offer. Cummins grabbed the opportunity to strut its newest stuff.

Cummins sparked a debate about fuel saving at this year’s IAA show (which alternates annually between the commercial and passenger side of things) in Hanover, Germany, by revealing several new innovations capable of improving the fuel efficiency of modern diesel engines.

Its stand demonstrated the global industry shift from being driven by emission outputs towards focusing on fuel economy improvements in the endeavour to protect customers from rising fuel prices.

“With fuel prices rising steeply, we foresee the trend in engine downsizing – making them smaller and lighter – gathering pace,” said Mark Firth, executive director for product line management and marketing. “In parallel, both engine and vehicle manufacturers are striving to maintain or increase the power outputs from their products.”

This led to Cummins developing various next-generation technologies and enhancements to meet this significant engineering challenge, including:

• A next-generation variable geometry turbocharger (VGT), featuring a common platform that can be tailored to meet the needs of individual customers without re-engineering. It also has a high efficiency compressor stage that delivers improved fuel economy, integrated actuator cooling, enhanced load balance, and improvements to the turbine seal rings and oil slinger. The VGT has the ability to apply a new actuator (a type of motor for moving or controlling mechanisms) for reduced packaging and plumbing on heavy duty applications. The corresponding reduction in complexity and materials used contributes to a reduction in weight (two kilograms) and cost (20 percent) over the model it replaced.

• A next-generation variable geometry turbocharger (VGT), featuring a common platform that can be tailored to meet the needs of individual customers without re-engineering. It also has a high efficiency compressor stage that delivers improved fuel economy, integrated actuator cooling, enhanced load balance, and improvements to the turbine seal rings and oil slinger. The VGT has the ability to apply a new actuator (a type of motor for moving or controlling mechanisms) for reduced packaging and plumbing on heavy duty applications. The corresponding reduction in complexity and materials used contributes to a reduction in weight (two kilograms) and cost (20 percent) over the model it replaced.

• Advanced waste heat turbine expander prototypes, which use a thermodynamic Organic Rankine Cycle to capture what would otherwise be lost energy in the form of heat. It in turn converts this into useful mechanical or electrical power capable of reducing a vehicle’s fuel consumption by five percent, delivering fuel savings of up to €4 500 (R51 058) per annum.

• Two-stage turbocharging systems with flexible architecture. These systems can efficiently integrate and package two fixed geometry, wastegate or variable geometry turbos in a series to deliver higher power density, increased boost, and greater airflow, while extending altitude air handling capabilities through the Holset Rotary Turbine Control (RTC). The RTC is a patented channelling technology, integrated into the turbine housing, that directs exhaust gas to selected “ports” for limited exhaust control capabilities.

• Two-stage turbocharging systems with flexible architecture. These systems can efficiently integrate and package two fixed geometry, wastegate or variable geometry turbos in a series to deliver higher power density, increased boost, and greater airflow, while extending altitude air handling capabilities through the Holset Rotary Turbine Control (RTC). The RTC is a patented channelling technology, integrated into the turbine housing, that directs exhaust gas to selected “ports” for limited exhaust control capabilities.

Firth mentioned that the head of engine development at a major European manufacturer told him that priority number one is fuel efficiency, priority number two is fuel efficiency and priority number three … well, you get the idea.

“While there were without doubt more high profile products launched at IAA Hanover, we believe none will have as far-reaching implications for the commercial vehicle industry as our next-generation technologies,” said Firth. “Only in time will their influence become clear, but that goes with the territory when you’re pushing technological boundaries.”

And this isn’t the only area where Cummins is pushing boundaries – Cummins Generator Technologies announced the development of its first motor generator, with CorePlus technology, at the IAA.

The decision to invest in this technology was sparked by the company’s belief that there is a strong market for engine electrification in medium and heavy duty commercial vehicles – and Cummins wanted to ensure its global position in this sector.

The Cummins CorePlus Motor Generator is available with power, torque and performance characteristics suitable for hybrid systems, electric vehicle designs, range extender solutions and electrical power generation in vehicles. It can be applied across a range of commercial vehicle applications such as buses, trucks and off-highway vehicles, and enhances vehicle fuel efficiency and emissions reduction.

The Cummins CorePlus Motor Generator is available with power, torque and performance characteristics suitable for hybrid systems, electric vehicle designs, range extender solutions and electrical power generation in vehicles. It can be applied across a range of commercial vehicle applications such as buses, trucks and off-highway vehicles, and enhances vehicle fuel efficiency and emissions reduction.

It also allows original equipment manufacturers to use their preferred engines and transmissions as the CorePlus Motor Generator is fitted between the vehicle’s engine and transmission. It has an integral rugged housing unit, which allows it to operate in the harsh environment of the engine bay, and the torsional strength to allow engine torque to be transferred through it to the transmission.

According to Vikrant Aggarwal, executive director for Cummins Generator Technologies, the CorePlus has a typical peak power of 90 kW and enhances efficiencies by more than 95 percent. It can also be used as a standalone generator for set applications.

“The electric machine is complemented by power electronics with Cummins’s embedded control algorithms to further extend performance and capability,” explained Aggarwal. “Alternate power

and performance nodes can also be developed cost effectively to meet specific customer needs.”

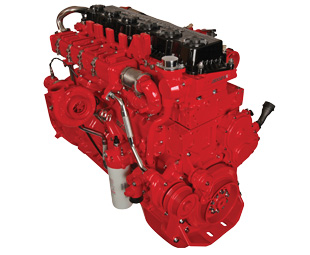

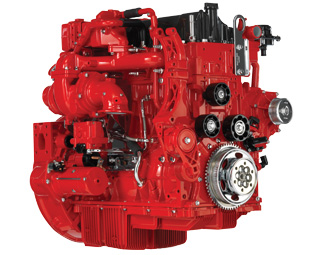

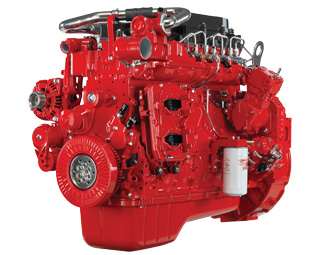

But wait! There’s more. The Cummins ISX12 G natural gas engine also made its European debut at the IAA. This 11,9-litre engine will get the North American commercial sector going early next year, with its 246,08 to 298,28 kW (330 to 400 hp) power range for alternative heavy-duty truck applications and peak torque of 1 966 Nm.

“Cummins has recognised the growing interest in natural gas products, developing two new heavy-duty additions for the product line,” explained Neil Pattison, director of automotive engine business for Europe, Middle East and Africa. “The ISX12 G was recently shown at the Mid-America Truck Show and is making its first appearance in Europe at IAA.”

He said the ISX12 G will be ready for the Environmental Protection Agency’s (EPA) 2013 emissions standards, with Euro-6 to follow, and that the larger ISX15 G version based on the 15-litre diesel engine will be available in 2015.

He said the ISX12 G will be ready for the Environmental Protection Agency’s (EPA) 2013 emissions standards, with Euro-6 to follow, and that the larger ISX15 G version based on the 15-litre diesel engine will be available in 2015.

The ISX12 G natural gas engine is based on the Cummins ISX12 diesel engine platform, the newest member of the Cummins heavy-duty engine family, and will operate on either compressed or liquefied natural gas. It will use spark-ignition with stoichiometric combustion (the ideal combustion process, where fuel is burned completely) and the cooled exhaust gas recirculation technology first introduced on the 8,9-litre ISL G.

The ISX12 G also features the same type of three-way-catalyst after-treatment used on the ISL G. This helps the stoichiometric engines to lower the oxides of nitrogen, carbon monoxide, hydrocarbons and formaldehyde to EPA-approved emissions standards. However, the engine is so clean that there is no need for a diesel particulate filter or a selective catalytic reduction system.

Manufactured in Cummins’s heavy-duty engine plant in Jamestown, New York, the ISX12 G will be the first Cummins gas engine offering an optional engine brake capability, and is compatible with a range of manual and automatic transmissions.

“The ISX12 G will provide operators with the heavy-duty performance, reliability and durability they expect from Cummins, with the environmental benefits of natural gas,” said Pattison. “The clean design means it is capable of meeting future emissions like the planned United States greenhouse gas and fuel economy regulations.”

The ISX15 G will also be using the same low-emission technologies as the 11,9-litre product, with ratings up to 372,85 kW (500 hp) and a maximum peak torque of 2 370 Nm.

It is clear that Cummins is gearing itself up toward delivering the best it can into the future. It will be interesting to see what the company will launch at IAA 2014.

Published by

Focus on Transport

focusmagsa