Technology in transit

The technical innovations highlighted in Truck Test 2015 go beyond the tracking and simulation software we’ve become accustomed to seeing. This year, Loadtech supplied some fascinating gadgets … GAVIN MYERS speaks to MD John Harrison.

According to Harrison, Truck Test 2015 is the ideal platform for an add-on supplier, such as Loadtech, to introduce new concepts and equipment. The company fitted on-board weighing and tyre-inflation systems to the Afrit trailers running in Truck Test 2015.

“Many companies do not have the resources to do a proper analysis of their needs and the results from the Truck Tests help them to make informed decisions on what to buy,” says Harrison.

“Loadtech started out in 1987 manufacturing weighing sensors (loadcells) for the industrial weighing market. Early in 2000 it designed and introduced the truck/trailer-mounted OnBoard weighing system. This was in the early days of overloading problems and Loadtech’s systems have made a significant difference in assisting its  customers to avoid overload penalties, while still making a profit in the face of reducing average payloads,” he says.

customers to avoid overload penalties, while still making a profit in the face of reducing average payloads,” he says.

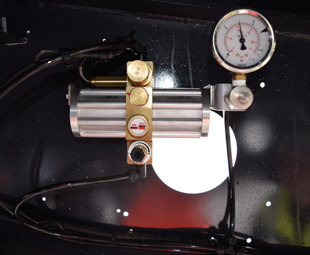

In Truck Test 2015, Loadtech showcased two different, but equally important, products for the extra-heavy market. The first is the well-known Loadtech OnBoard weighing system, while the second is the Vigia OnBoard mounted tyre monitoring and inflation system.

As far as the OnBoard weighing system is concerned, Harrison explains that this is fitted between the load and the chassis, on the truck and the trailer. “We obviously can’t measure beneath the wheels, like a normal platform scale does, so we weigh between the load and the chassis and add in the tare weight to get the gross weight.”

A display in the cab alerts the driver to the mass being loaded so that he can take responsibility for the loading process.

Harrison explains that loading trucks correctly, without some way of determining the weight, is extremely difficult. “Many remote operations do not have the luxury of a weighbridge to check the load. In these cases,  it is a necessity to have a Loadtech OnBoard weighing system fitted, so that the load can be monitored during the loading process. Our motto is ‘load correctly first time, every time’.”

it is a necessity to have a Loadtech OnBoard weighing system fitted, so that the load can be monitored during the loading process. Our motto is ‘load correctly first time, every time’.”

While this is, without doubt, a system any operator wouldn’t want to be without, it is the tyre inflation kits that will probably catch the attention of most operators interested in the test.

“This is a universal product in which anyone doing long-haul transport could be interested,” Harrison says. “The aim is for vehicles to avoid getting stuck on the side of the road in the event of a puncture, where they will lose time and incur the costs of roadside repair.”

According to Harrison, this system is especially important for deliveries that are time-sensitive. “If a delivery has a scheduled offloading slot and the truck is delayed en route with a flat tyre, the company has lost a tyre, has to pay for a roadside repair, and has lost the delivery slot. As a consequence, the load may be rejected,” he illustrates.

The tyre inflation system sources air from the trailer to maintain the preset pressure in the tyres. If there’s a leak or puncture, the pressure in the tyre starts to reduce. If it reduces below the preset pressure, air is continually pumped into the tyre in an attempt to maintain the operating pressure. The driver is alerted and he can make an informed decision on whether to stop immediately or continue on to his destination.

The tyre inflation system sources air from the trailer to maintain the preset pressure in the tyres. If there’s a leak or puncture, the pressure in the tyre starts to reduce. If it reduces below the preset pressure, air is continually pumped into the tyre in an attempt to maintain the operating pressure. The driver is alerted and he can make an informed decision on whether to stop immediately or continue on to his destination.

“In many other countries with long-distance operations, it is common to see these systems fitted. Why is it that our local operators do not see the same benefit and fit the systems to their vehicles?” Harrison muses.

Hopefully, Truck Test 2015 will go some way to changing that.

Published by

Focus on Transport

focusmagsa